© RnR Marine™, Inc.

2004-2026

All Rights Reserved

|

|

© RnR Marine™, Inc. 2004-2026 All Rights Reserved |

|

February 23, 2026 RnR-Marine™ Announcements:

|

If you are considering a T-Top, it is important to understand the differences in quality, strength, finish, longevity and resistance to the elements that welded stainless steel tubing provides versus welded aluminum pipe, which most T-Tops are made of. If you'll notice, almost all boat railings are stainless steel, with little or no aluminum used at all. Aluminum is often used on after market items since it is easier and cheaper to work with.

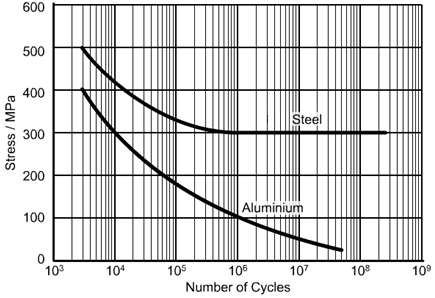

Plus, steel is 'strain rate sensitive', many aluminum structural grades are not. It is well known that steel displays positive strain rate performance. That is, at the higher rates of strain typically associated with crash events, steel has higher strength increases and consequently higher energy absorption at a given part weight.

The strength of aluminum welds is greatly decreased by welding, which reacts with the anodized aluminum producing hydrogen cracking. In addition, anodization (aluminum oxide) melts at approximately 3,600° F, while the aluminum underneath melts at about 1,200° F. Very few welding operators can develop a technique and find a machine that lets them manipulate the AC TIG arc so that it 1) penetrates the anodized coating and 2) establishes a good weld puddle without adding so much heat that the puddle rolls out of the joint or the arc blows through the base metal. This high heat can ruin the aluminum tubing!

By comparison, Numerical Controlled (NC) orbital welded (the process RNR uses) low-carbon (304L and 316) stainless welds are often stronger than the source material. In addition, RNR-Marine does NOT butt-weld tubing (welding a cut end to a pipe). RNR-Marine TIG welds a thick, cast 316 stainless steel fitting at EVERY end fitting, creating a joint that will virtually last forever!

304L (low carbon) and 316L (low carbon with molybdenum) stainless steel maintains its luster,

shine and strength over time.

Passivation and electropolishing the stainless remove any surface carbon and iron molecules to provide a very

saltwater resistant surface. Aluminum does not resist corrosion well, except by anodizing (building an oxide layer

on the surface). Welding removes this oxidation at the most critical points, the joints, which will corrode

(by pitting) over time, and fail due to fatigue.

"

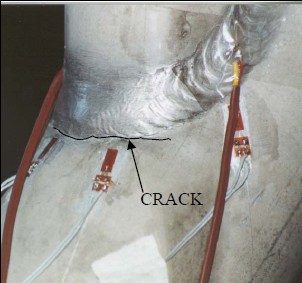

I have a cross brace on my t-top that has cracked just inside the weld on both ends.

I have been calling around and can't seem to find anyone interested in coming out

to at least give me an estimate.

I have been told that they will most likely

have to unhook all electronics and lift the t-top off to fix.

" - Reel Outrage, FL

http://forums.floridasportsman.com/showthread.php?6053-T-TOP-REPAIR-HELP

"

I live in Normandy Beach NJ. My boat is 23 foot Boston Whaler Outrage with a T-Top made out of fiberglass. My T-Top has a crack on the port side of the front support pole. The crack is right on an old welded spot on the aluminum pole.

I was wondering if anyone can recommend someone that could come to my house and weld the boat right at our dock. I would rather not drop the boat off if I don't have to. Thanks for all of your help.

" - Jbender5, NJ

http://www.boatered.com/forum/topic.asp?TOPIC_ID=147287

"

Our T-top was basically cut in half, just all spliced together with rubber bands

and duct tape and anything we could find to splice all the breaks in the poles.

Because every pole - there's eight pole -; every pole was completely severed,

and most of them in two or three places. And the T-top was just dancing above our heads.

I mean, I can't believe it even stayed on.

It's made of aluminum, so it looks real good and won't rust and all that stuff,

but as far as taking the jarring of moving back and forth,

waves breaking over the whole boat, and the wind and the constant pounding - it's aluminum,

so it doesn't bend as much. It's more brittle, I guess. And it cracked at the welds.

Right across every weld on the uprights - not every weld, but a lot of the welds.

I guess the heat weakens or something. And then it didn't crack right at the weld,

it was just right next to the weld.

" - Ralph and Bob Brown, The Florida Duo that Crossed the Atlantic in a Multihull Flats Boat

http://madmariner.com/seamanship/piloting/story/Q_AND_A_RALPH_BROWN_ROBERT_BROWN_021811_SP

"

I didn't do it -but the boat I bought was left in the salt spray

and it now has pits on the port side of the T-top (Birdsall or Bluewater) .

They are not noticeable by touch. It all feels smooth. But they look like stains all over

" - MakoTx, Houston, TX

http://www.thehulltruth.com/boating-forum/274227-t-top-clean-restore-pitted-aluminum.html

"

I have a 2003 Montauk 170. It has a rather large T-Top on it,

I will be taking it off soon. Mostly for storage issues.

I will say that it changes the handling of the boat - a little top heavy,

knocks off the top end a good bit and changes the feel of towing it on the highway.

" - sloppyrudder

http://www.whalercentral.com/forum/viewthread.php?thread_id=11713&pid=73112

"

I have a weld on the T-Top that cracked then broke at the weld.

" - Z71. Cross Roads / Denton, TX

http://texasfishingforum.com/forums/ubbthreads.php/topics/5851681/Re_T_Top_weld

"

I have a T-Top made from aluminum.

It is high quality, but it snapped right next to a weld.

The aluminum pipe itself snapped,

and part of the break followed the contour of the weld joint itself.

" - thunnus.

http://www.thehulltruth.com/boating-forum/140943-aluminum-tower-snapped-can-welded.html

"

Whenever there's movement or flex in the pipework On the pipework

theres usually barely visible lines radiating around the radius of the tubing

an inch or so from the weld.

It looks like the anodizing is cracking but it's actually metal fatigue.

I have had to have a few spots repaired on mine where it cracked all the way around.

" - no problem1. Pasadena, Maryland

http://www.thehulltruth.com/boating-forum/330593-mako-t-top-snow.html

"

New to THT but a long time boater. I have a 2005 22 angler with a hard top t top that is

cracking in numerous places on the vertical tubes. I have added three horizontal

supports and have gusseted the bottom horizantal bit still have cracking in other places.

has any one else had this same problem

thank you

" - Byrdgreen

http://www.thehulltruth.com/boating-forum/321157-angler-22-2005-t-top-issues.html

"

Noticed some cracks in my T top on the way out.

Made some Macguyver repairs with rope and zip ties and pressed on ...

" - SCSuperfly, Moncks Corner, SC

http://www.charlestonfishing.com/forum/topic.asp?TOPIC_ID=108765

"

Was out cleaning the Sea Pro and looked up at the TTop and noticed a crack

in the horizontal tubing That ties the two vertical tubes together.

The entire bottom of the tube is cracked. I tried to call the dealer

but they haven't returned my call, yet. Will this be under warranty?

The boat is 18 months old. Thanks

" - bletort, Ocean Springs, MS

http://www.thehulltruth.com/boating-forum/117208-ttop-crack-aluminum.html

"

OK, this winter my fiberglass T-top cracked in half.

It broke at a bolt hole and sheared the upper third completely off.

It's still secured to the aluminum frame but I plan to take it to a fiberglass repair shop

and have it mended as well as have some minor cracks in the frame repaired

while the top is off.

" - atcangler, Fleming Island, FL

http://forums.floridasportsman.com/forum/marine-electronics/how-disconncect-plugs-gps-and-vhf-without-cutting-cables

"

Does anybody know someone that can weld some cracked tubes on a T-top.

" ... "

It is just a support brace from console to top in front of the windshield.

Also that brace caused the main pole from floor to the top to shear.

That pole is broke completely and has a crack right up top. 3 places to weld.

The sheared pole might need more support after it is welded.

I was told that the whole T-top will have to come out. Is that true or can it be avoided.

Thanks Steve.

" - hydra2450, Charleston, SC

"

I had a stress crack on one leg of mine and we did not have to remove it to fix weld it

but it takes a LOT of COVERING UP. Sea Pro 210cc

" - tprice, Charleston, SC

http://www.charlestonfishing.com/forum/topic.asp?TOPIC_ID=66437

"

Noticed a crack in a joint weld in my aluminum T-Top while wrapping the boat up

for the season. I would appreciate any info on marine welders in the Falmouth/Mashpee area

to contact for a late winter, early spring fix. Thanks in advance.

" - garo 22, MA

http://www.thehulltruth.com/northeast/196583-welder-options.html

"

We have a 247 Advance and several of our welds on the T-top are breaking.

Has anyone had this problem? We are in South Carolina and have to run the boat pretty hard

to get to the gulf-stream. I would appreciate any feedback from people who have had a

similar problem.

" - PalmettoGrady, SC

http://www.greatgrady.com/forum/viewtopic.php?p=51328

"

T-Top Aluminum repair. I noticed a crack in the weld and I was wondering if JB weld would

do the trick for a while at least until the winter or if there is another option available.

- boatowner1122, North Texas

"

I've got the same problem with mine, 04 boat.

Naturally its where wiring leads to the electronics box. Wonder if anyone has had succuss

repairing one with alumalloy or similar type products which work like solder? Brian

" - big bass, Greensboro, NC

"

Ditto. Had the same problem. Thought I would "take it easy on her" and try to delay the repair.

BAD IDEA. When the original crack gave way after hitting an unexpected wave,

the stress created on the other welds caused two more to break,

which effectively trippled the cost of repair. My repair bill was about $200,

but I removed and reinstalled my canvas top and e-box myself which probably saved me $100.

Get it fixed now unless you want to spend more $ than necessary.

___ Mac Solo, 1985 25' Parker Sou'Wester---2005 F250 Yamaha

"- originalsin, OIB NC

http://www.thehulltruth.com/boating-forum/56711-t-top-aluminum-repair.html

"

The fairy tale is that the crap doesnt corrode. The hull truthis you have to watch

aluminum for pitting along with a few others : stress cracking corrosion,

groove corrosion,galvanic corrosion....can be nasty stuff ...

"- captct, Vancouver Island

http://www.thehulltruth.com/boating-forum/155242-pilothouse.html

"

Can anybody give me an idea how much it should cost to get an area on my T-top welded.

It is a crack through one of the brackets that attach the T-top to the center console.

About 3 inches long. Tried to post photos but can't figure it out.

I can trailer to get the work done, but obviously don't want to have to drag the boat around

to several different guys to compare prices. Hopefully I can get the photos to post.

Also if anyone in the Wilmington, NC area can recommend a welder I would appreciate it. Thanks!

"- gb, Wilmington, NC

http://www.thehulltruth.com/boating-forum/40611-t-top-welding.html

"

I have an [Angler] '04 230 VBX with a factory T top, I love my boat.

However I am extremely disappointed with the T top.

The welds are beginning to fail, the top is deflecting from side to side,

and now I am starting to have spider cracks show up in the fiberglass around the mounting plates.

I have gotten estimates to replace/repair the existing structure,

most want to replace it saying that the structure was not a sound design to begin with.

I have tried to contact angler with no response yet.

I was wondering if anyone has had a similar experience and what recourse should I take.

"- jab001

http://forums.iboats.com/showthread.php?t=235668

"

Anyone who deals with aluminum long enough has cracks.

As good as it is for specific purposes, that is what aluminum does, it cracks.

Particularly if it was anodized before it was welded.

Aluminum has some great properties but fatigue strength is not necessarily one of them.

Strip the paint from the suspected area and do, or have someone do it for you,

a dye penetrant check. This will verify there is indeed a crack and determine the extent of it.

Although the crack can be welded over,

if it were mine I would have some reinforcing gussets welded in to support the

welded over area and to minimize the likelyhood of future cracks. None of this should be

difficult for an experienced welder.

"- jethro1

http://www.thehulltruth.com/boating-forum/80842-crack-armstrong-bracket.html

"

You are going to need a LOT of welder to burn the anodizing off as you go.

And, then be ready for the towers to come back to you in a few years with cracks in them.

My boat tower is aluminum, and the anodizing has pitted badly,

and the tower cracks in a new spot every 2 years. Anodized aluminum kinda sucks, IMHO.

I will rebuild it in stainless next year...

we just got done repairing it all over the place for this season.

So it's time to fish, and break my ugly pitted tower.

I'd rather use mill spec aluminum TUBE, instead of pipe, and just paint it in the first place.

My first tower was like that. No cracks in 7 years, no pitting.

I got talked into the anodized by the boat shop. Never again.

To typically get through the anodizing, you need to run about 210-230 amps,

and set for a lot of cleaning with your sq. wave.

The extra heat is to push that turd out of the way,

and to compensate for the extra cleaning vs. penetraion.

Then, you bump back your welds to push the anodizing turd to the outer edges.

clean with acetone, and paint. I hate doing it. I'd rather tig weld rusted trailers all day,

upside down. It can be made to look good with some practice and tuning your welder.

" - Rojodiablo, Moderator, www.WeldingWeb.com

http://weldingweb.com/showthread.php?t=1159

"

All I do is cut it and weld, works fine,

just minor impurities from the anodizing burning off.

we paint over the welds to protect them, rustoleum aluminum is an exact match.

" - 500HpSilverado, WeldingWeb Tradesman, www.WeldingWeb.com

http://weldingweb.com/showthread.php?t=42942

"

Sometimes, you paint over the welds with some chrome paint, or clear epoxy paint.

It's really not too much of a problem.

Some guys will wax the welds to keep saltwater from getting them too fast.

I am not the biggest fan of anodized aluminum in the ocean. With electrolosys,

you get some pitting on the aluminum within a few years.

And then, you have to sand and paint it, or start chasing out the crap. Endless pain in the butt.

But with steady waxing, and good electrical grounds, it will last for years.

"- Rojodiablo, Master Welder, www.WeldingWeb.com

http://weldingweb.com/showthread.php?t=24869

" In building a hardtop frame for my boat I carefully sanded away the anodization from the weld area. After the project is done if you wish to brighten up the welded area you can brush the weld with some chrome colored paint. " - skypoke2 http://www.chaski.com/homemachinist/viewtopic.php?f=12&t=28400